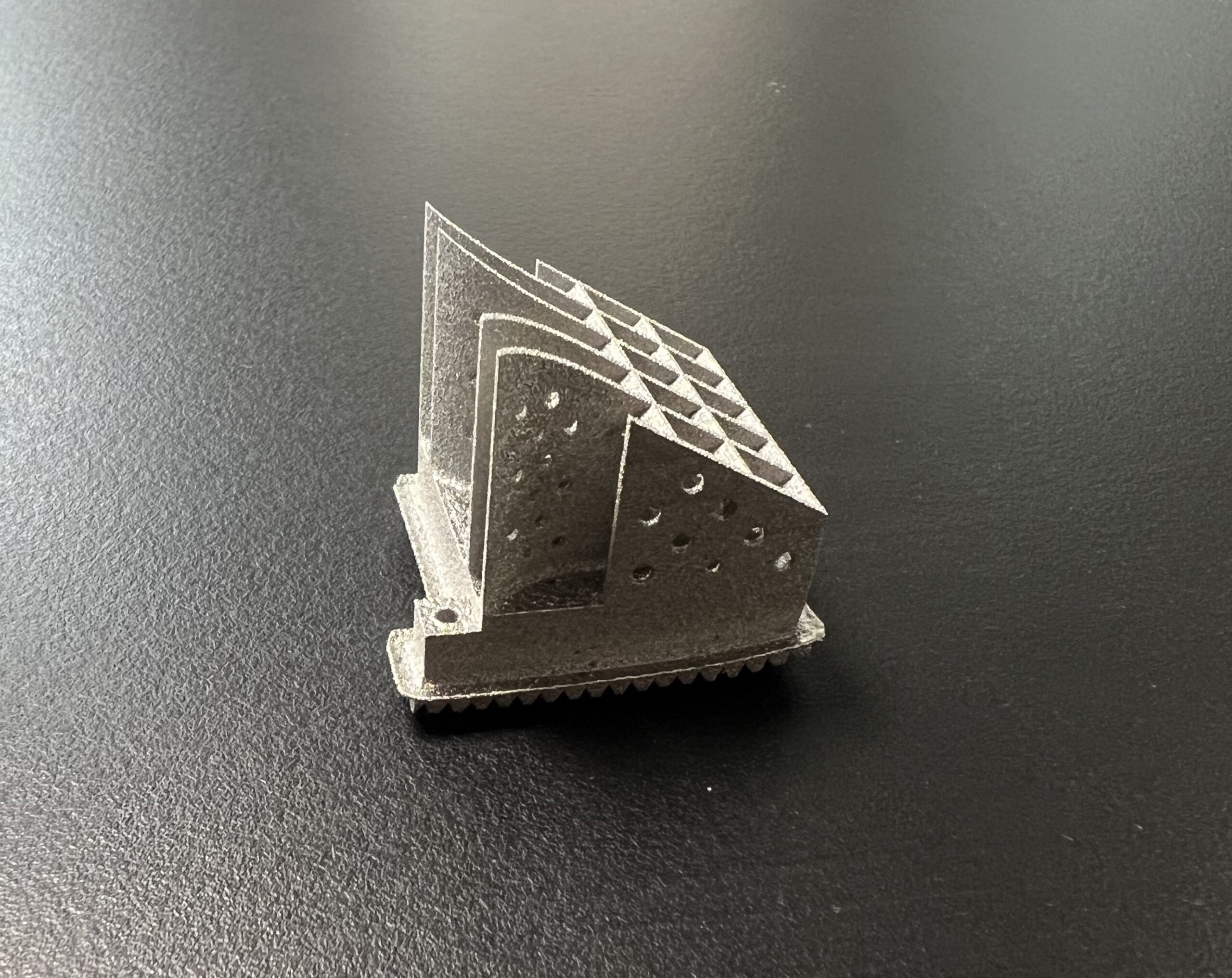

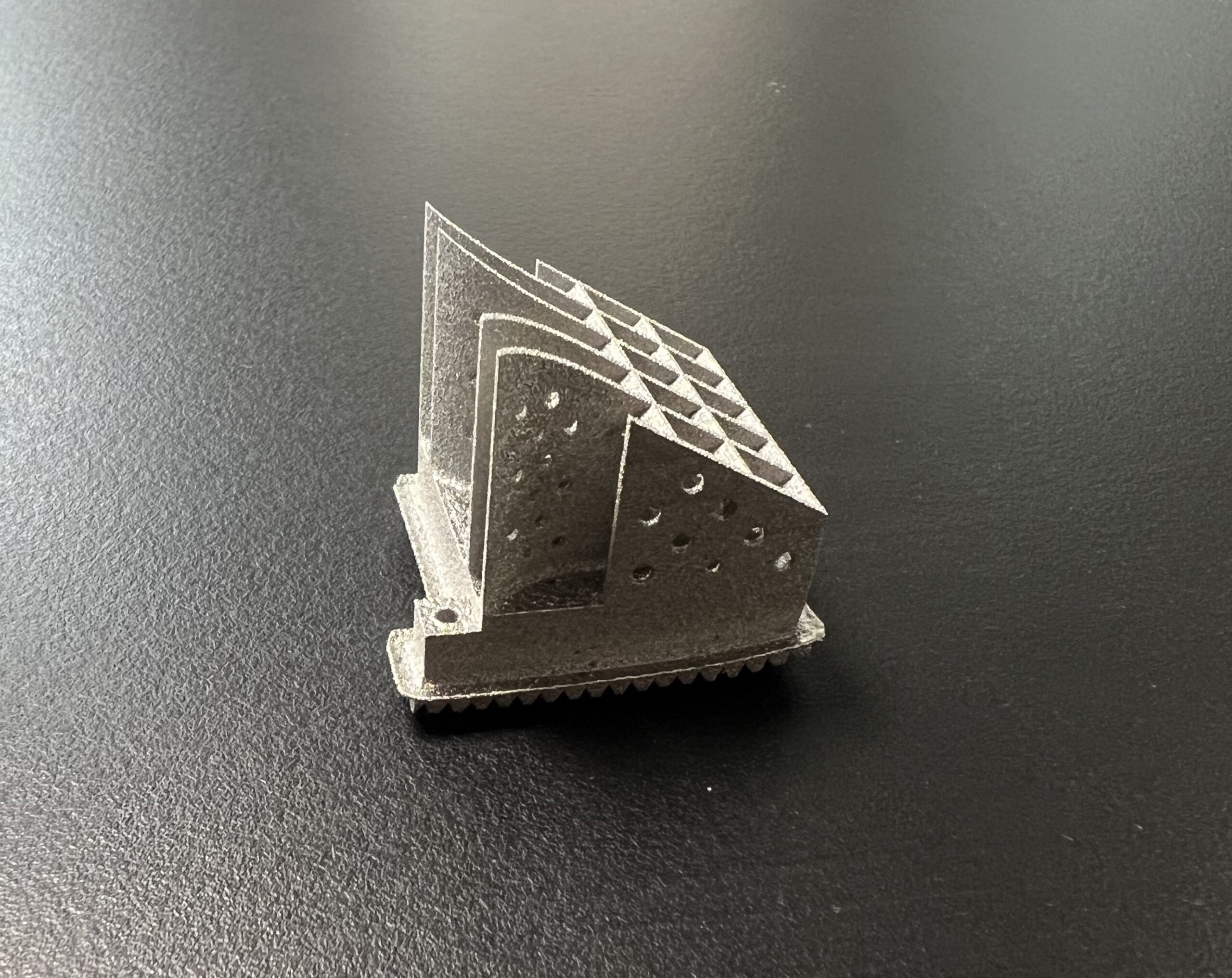

WHAT IS A

LASER POWDER BED FUSION?

Laser powder bed fusion (LPBF) is an additive manufacturing (AM) technology that uses a laser to locally melt metal powder in a layer-by-layer fashion according to a user-supplied CAD model. The final product is a three-dimensional part intended to replicate the user-supplied CAD (Computer-aided design) geometry.

MACHINE

SPECIFICATIONS

- Model: Aconity MIDI

- Maximum possible build space: Ø 170 mm x H 200 mm

- Laser power: 400 W

- Number of lasers: 2

- Minimum build layer thickness: 10 µm

- Induction heater to pre-heat build platform up to 1200° C

- Pyrometer to detect overheating and enable measurements of spatial temperature distribution during the build

- Optical camera for in-process monitoring at 30 frames per second (fps)

AconitySIEVE Machine Summary

- Total sieving area: 200 x 535 mm²

- Adjustable flow of material

- Ultrasonic generator with adjustable frequency for high throughput rates

- Additional mechanical vibration

- Exchange of sieving screens

- Fast material exchange

- Powder throughput: 100-150 kg/h (Aluminium)

AconitySIEVE Inertization

- Touchscreen controlled PLC for variable sieving cycles (amplitude / time)

- Inertization with Argon 4.6 / Nitrogen for sieving of reactive materials

- Adjustable residual oxygen content of min < 500 ppm ·Inert gas consumption of < 5 l/min during process

Frequently Asked Questions

Essentially, any weldable metal can be printed using this machine, including steel, nickel, titanium, and aluminum alloys.

The size of a printed part is limited by dimensions of the build space: Ø 170 mm (6.6”) x H 200 mm (7.9”).

Spatial resolution is governed largely by minimum build layer thickness: 10 μm.

The print time depends on the part size, geometry, and laser settings. Time can range from several hours to more than a day.

This machine has an open architecture, meaning that the operator has nearly complete control over the process settings.

Geometries that are too complex or too intricate to be manufactured using conventional manufacturing techniques are ideally suited for LPBF.

If you would like to learn more or are ready to have a part printed, contact Alik Nielsen.